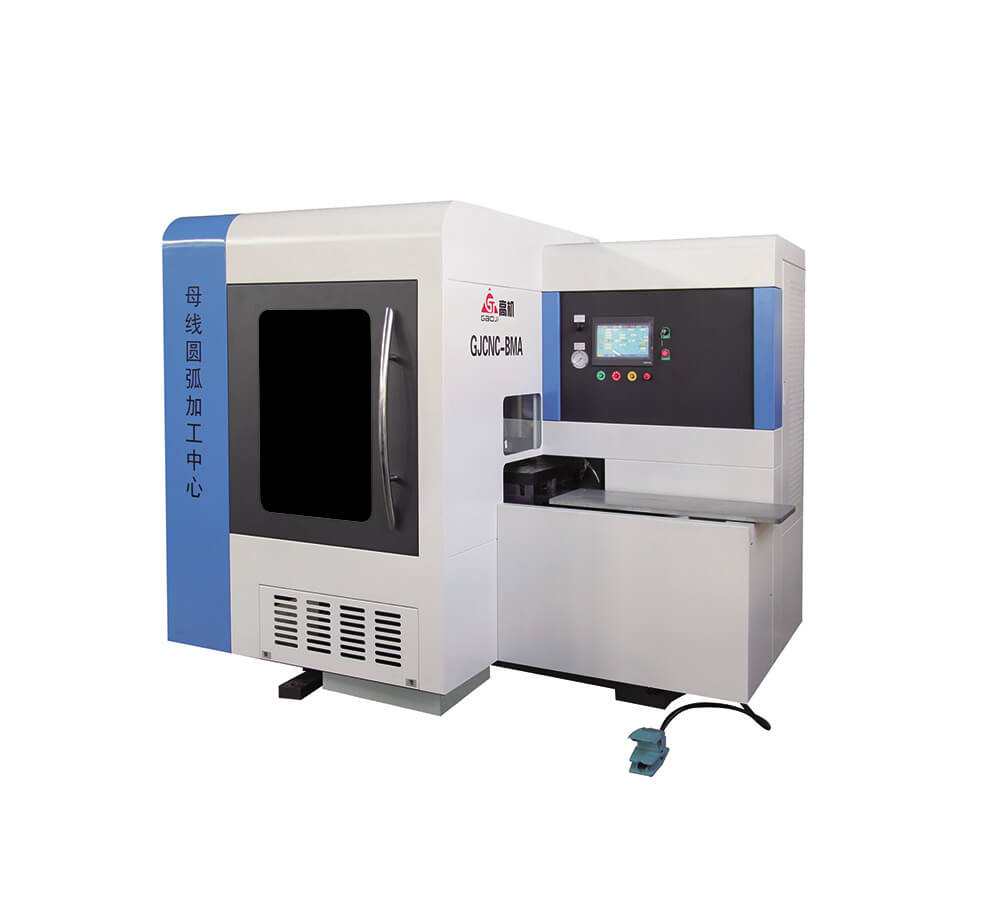

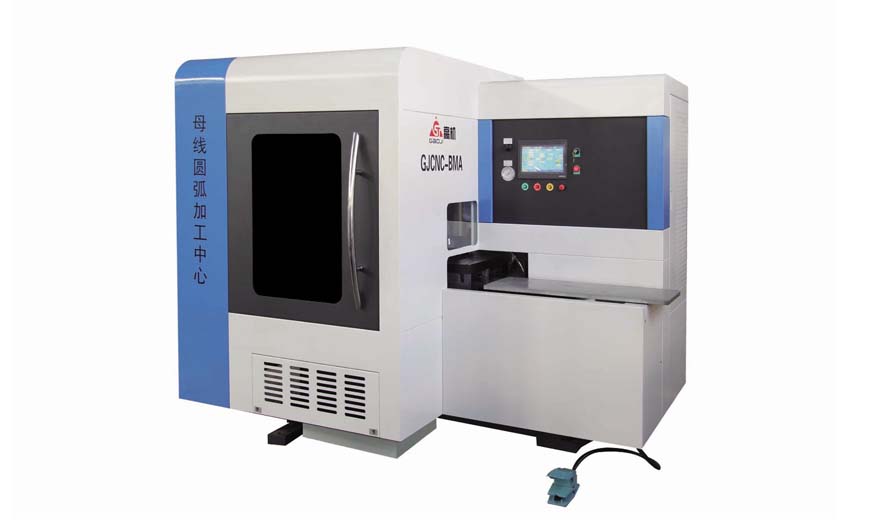

Tuam Tshoj pheej yig tus nqi CNC tsis siv neeg tooj liab High Effiency ua dabtsi yog khoov Punching tej tshuab Busbar Arc Chamfering tshuab

Tsis muaj teeb meem cov neeg siv khoom tshiab lossis cov neeg siv khoom tsis ntev los no, Peb ntseeg tias muaj kev qhia ntev thiab kev ntseeg siab rau Tuam Tshoj Tus nqi pheej yig CNC Automatic Copper High Effiency Processing Bending Punching Cutting Machine Busbar Arc Chamfering Machine, Qhov tsis tu ncua ntawm cov khoom lag luam qib siab ua ke nrog peb qhov tshwj xeeb ua ntej thiab tom qab muag kev txhawb nqa kom muaj kev sib tw thoob ntiaj teb kev lag luam nce ntxiv.

Tsis muaj teeb meem cov neeg siv khoom tshiab lossis cov neeg siv khoom qub, Peb ntseeg hais tias ntev ntev thiab kev sib raug zoo rau kev ntseeg siabTuam Tshoj Busbar Chamfering Tshuab thiab Tooj Busbar Tshuab, Peb lub tuam txhab txuas ntxiv ua haujlwm rau cov neeg siv khoom zoo, tus nqi sib tw thiab xa khoom raws sijhawm. Peb zoo siab txais tos cov phooj ywg los ntawm thoob plaws lub ntiaj teb los koom tes nrog peb thiab nthuav peb txoj kev lag luam. Yog tias koj txaus siab rau peb cov khoom, koj yuav tsum xav tiv tauj peb. Peb xav muab cov ntaub ntawv ntxiv rau koj.

Khoom Paub meej

CNC busbar milling tshuab feem ntau ua haujlwm hauv milling fillet thiab loj fillet nyob rau hauv lub busbar. Nws cia li generates qhov kev pab cuam code thiab xa cov code rau cov khoom siv raws li qhov yuav tsum tau ntawm lub busbar specification thiab cov ntaub ntawv tawm tswv yim mus rau lub zaub screen. Nws yog ib qho yooj yim rau kev khiav lag luam thiab tuaj yeem siv cov khoom siv busbar arc nrog zoo saib.

Qhov zoo

Lub tshuab no yog siv los ua cov khoom seem arc machining rau busbar hau nrog H≤3-15mm, w≤140mm thiab L≥280mm.

Lub taub hau bar yuav raug machined rau cov duab nrog cov qauv ruaj.

Cov clamps txais kev siv tshuab nruab nrab tsis siv neeg los nias lub taub hau zoo dua mus rau qhov taw tes quab yuam.

Lub koob tshuaj siv rau ntawm lub taub hau nias kom ruaj ntseg ntawm workpiece, ua kom zoo dua machining nto nyhuv.

Lub ntiaj teb tus qauv BT40 cov cuab yeej tuav yog siv los hloov cov hniav yooj yim, zoo rigidity thiab siab raug.

Lub tshuab no siv cov khoom siv high-precision pob screws thiab linear qhia. Heavy-load loj-loj phau ntawv qhia ntsia tau raug xaiv los muab kev nruj dua ntawm tag nrho lub tshuab, txo qis kev co thiab suab nrov, txhim kho cov khoom ua haujlwm zoo thiab ua kom cov neeg ua haujlwm siab thiab ua haujlwm zoo.

Siv cov khoom siv hauv tsev thiab lub ntiaj teb nto moo hom, lub tshuab no yog lub neej ua haujlwm ntev thiab tuaj yeem lav qhov zoo.

Cov kev pab cuam siv nyob rau hauv lub tshuab no yog cov embedded tsis siv neeg graphics programming software tsim los ntawm peb lub tuam txhab, realizing lub automation nyob rau hauv lub programming. Tus neeg teb xov tooj tsis tas yuav nkag siab ntau cov lej, thiab nws tsis tas yuav paub yuav ua li cas khiav lub chaw machining ib txwm muaj. Tus neeg teb xov tooj tsuas yog yuav tsum tau nkag mus rau ntau qhov tsis sib xws los ntawm kev xa mus rau cov duab kos, thiab cov cuab yeej yuav tsim kom tau txais cov lej tshuab. Nws yuav siv sij hawm luv dua li phau ntawv programming thiab tshem tawm lub peev xwm ntawm cov lej yuam kev tshwm sim los ntawm phau ntawv programming.

Busbar machined nyob rau hauv lub tshuab no yog zoo saib, tsis muaj taw tes tawm, nqaim lub txee loj kom txuag tau qhov chaw thiab remarkably txo tau cov tooj liab.

Tsis muaj teeb meem cov neeg siv khoom tshiab lossis cov neeg siv khoom tsis ntev los no, Peb ntseeg tias muaj kev qhia ntev thiab kev ntseeg siab rau Tuam Tshoj Tus nqi pheej yig CNC Automatic Copper High Effiency Processing Bending Punching Cutting Machine Busbar Arc Chamfering Machine, Qhov tsis tu ncua ntawm cov khoom lag luam qib siab ua ke nrog peb qhov tshwj xeeb ua ntej thiab tom qab muag kev txhawb nqa kom muaj kev sib tw thoob ntiaj teb kev lag luam nce ntxiv.

Tuam Tshoj pheej yig tus nqiTuam Tshoj Busbar Chamfering Tshuab thiab Tooj Busbar Tshuab, Peb lub tuam txhab txuas ntxiv ua haujlwm rau cov neeg siv khoom zoo, tus nqi sib tw thiab xa khoom raws sijhawm. Peb zoo siab txais tos cov phooj ywg los ntawm thoob plaws lub ntiaj teb los koom tes nrog peb thiab nthuav peb txoj kev lag luam. Yog tias koj txaus siab rau peb cov khoom, koj yuav tsum xav tiv tauj peb. Peb xav muab cov ntaub ntawv ntxiv rau koj.

Kev teeb tsa

| Qhov Loj (mm) | Qhov hnyav (kg) | Lub Rooj Ua Haujlwm Loj (mm) | Cua Source (Mpa) | Tag nrho lub zog (kw) |

| 2500 * 2000 hli | 3300 ib | 350 * 900 hli | 0.5 ~ 0.9 hli | 11.5 |

Technical Parameters

| Lub cev muaj zog (kw) | 7.5 | Servo zog (kw) | 2 * 1.3 | Qhov siab tshaj plaws (Nm) | 62 |

| Tool Holder Model | BT40 | Txoj kab uas hla (mm) | 100 | Ceev ntawm spindle (RPM) | 1000 |

| Khoom dav (mm) | 30-140 Nws | Yam khoom ntev (mm) | 110 | Khoom Thickness (mm) | 3 ~ 15 |

| X-Axis Stoke (mm) | 250 | Y-Axis Stoke (mm) | 350 | Txoj hauj lwm ceev ceev (mm/min) | 1500 |

| Pitch ntawm Ballscrew (mm) | 10 | Qhov tseeb qhov tseeb (mm) | 0.03 ib | Pub ceev (mm / min) | 1200 |