Tuam Tshoj Chaw Tsim Khoom Tuam Tshoj CNC Multifunction Busbar Ua Tshuab Nrog Kub Muag

"Raws li kev lag luam hauv tsev thiab nthuav dav kev lag luam txawv teb chaws" yog peb txoj kev loj hlob rau Tuam Tshoj Chaw Tsim Khoom Tuam Tshoj CNC Multifunction Busbar Processing Machine nrog Kub Muag, Peb tsom mus rau kev ua cov khoom lag luam zoo tshaj plaws los muab kev pabcuam rau peb cov neeg siv khoom los tsim kom muaj kev sib hlub mus sij hawm ntev.

"Raws li kev ua lag luam hauv tsev thiab nthuav dav kev lag luam txawv teb chaws" yog peb txoj kev loj hlob rauTuam Tshoj CNC Ua Tshuab, Tus nqi zoo yog dab tsi? Peb muab rau cov neeg siv khoom nrog tus nqi Hoobkas. Hauv lub hauv paus ntawm qhov zoo, kev ua haujlwm zoo yuav tsum tau them sai sai rau thiab tswj cov nyiaj tau los qis thiab noj qab haus huv. Kev xa khoom sai yog dab tsi? Peb ua qhov kev xa khoom raws li cov neeg siv khoom xav tau. Txawm hais tias lub sijhawm xa khoom nyob ntawm qhov ntau thiab tsawg ntawm kev txiav txim thiab qhov nyuaj ntawm nws, peb tseem sim muab cov khoom thiab cov kev daws teeb meem raws sijhawm. Vam tias peb tuaj yeem muaj kev sib raug zoo ua lag luam mus sij hawm ntev.

Kev piav qhia txog khoom

BM303-S-3 Series yog cov tshuab ua haujlwm ntau yam busbar tsim los ntawm peb lub tuam txhab (tus lej patent: CN200620086068.7), thiab thawj lub tshuab xuas nrig ntaus turret hauv Suav teb. Cov khoom siv no tuaj yeem ua xuas nrig ntaus, txiav thiab khoov tib lub sijhawm.

Qhov zoo

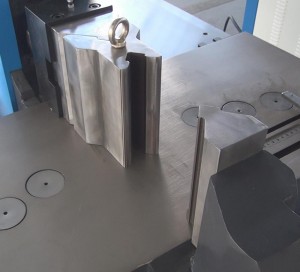

Nrog cov tuag tsim nyog, lub tshuab xuas nrig tuaj yeem ua cov qhov puag ncig, oblong thiab square lossis emboss thaj tsam 60 * 120mm ntawm lub busbar.

Chav tsev no siv cov khoom siv tuag turret-hom, muaj peev xwm khaws cia yim lub tshuab xuas nrig lossis embossing tuag, tus neeg teb xov tooj tuaj yeem xaiv ib lub tshuab xuas nrig hauv 10 vib nas this lossis hloov pauv tag nrho cov tshuab xuas nrig hauv 3 feeb.

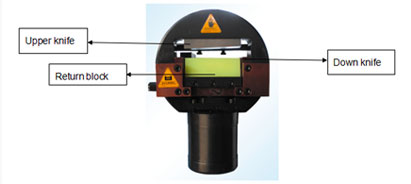

Lub tshuab txiav xaiv ib txoj kev txiav ib zaug, tsis txhob muab pov tseg thaum txiav cov khoom.

Thiab chav tsev no siv cov qauv puag ncig uas ua tau zoo thiab muaj peev xwm ua haujlwm tau ntev.

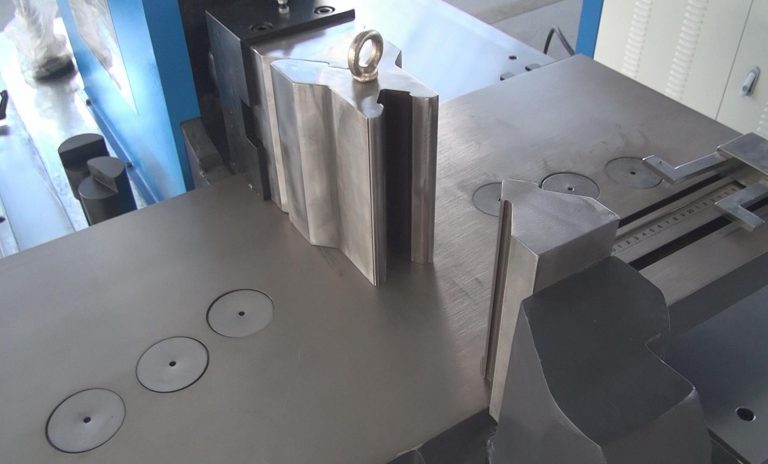

Lub tshuab khoov tuaj yeem ua cov txheej txheem khoov theem, khoov ntsug, khoov lub luj tshib, txuas lub davhlau ya nyob twg, Z-puab lossis khoov ntswj los ntawm kev hloov cov tuag.

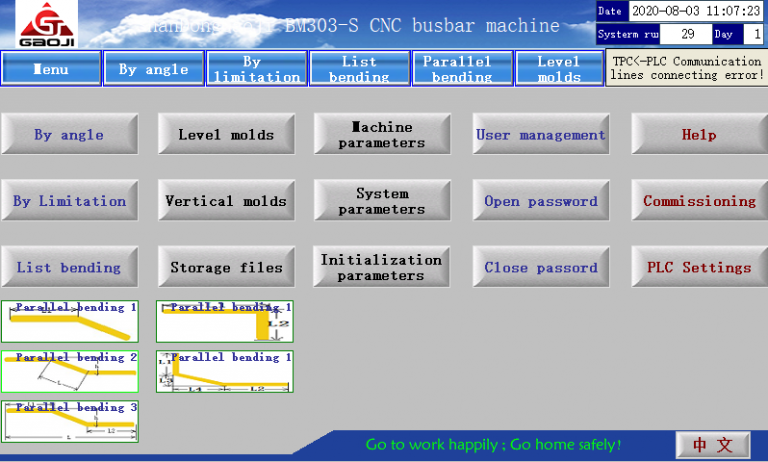

Chav tsev no yog tsim los kom tswj tau los ntawm PLC qhov chaw, cov khoom no koom tes nrog peb qhov kev tswj hwm tuaj yeem ua kom koj muaj kev paub ua haujlwm yooj yim thiab ua haujlwm raug siab, thiab tag nrho cov khoom khoov tso rau ntawm lub platform ywj pheej uas ua kom tag nrho peb chav tuaj yeem ua haujlwm tib lub sijhawm.

Vaj huam sib luag tswj, tib neeg-tshuab interface: nws software yooj yim rau kev khiav lag luam, muaj lub luag haujlwm khaws cia, thiab yooj yim rau kev ua haujlwm rov ua dua. Kev tswj hwm machining siv txoj kev tswj tus lej, thiab qhov tseeb machining yog siab.

"Raws li kev lag luam hauv tsev thiab nthuav dav kev lag luam txawv teb chaws" yog peb txoj kev loj hlob rau Tuam Tshoj Chaw Tsim Khoom Tuam Tshoj CNC Multifunction Busbar Processing Machine nrog Kub Muag, Peb tsom mus rau kev ua cov khoom lag luam zoo tshaj plaws los muab kev pabcuam rau peb cov neeg siv khoom los tsim kom muaj kev sib hlub mus sij hawm ntev.

Tuam Tshoj Tus Neeg Muag KhoomTuam Tshoj CNC Ua Tshuab, Tus nqi zoo yog dab tsi? Peb muab rau cov neeg siv khoom nrog tus nqi Hoobkas. Hauv lub hauv paus ntawm qhov zoo, kev ua haujlwm zoo yuav tsum tau them sai sai rau thiab tswj cov nyiaj tau los qis thiab noj qab haus huv. Kev xa khoom sai yog dab tsi? Peb ua qhov kev xa khoom raws li cov neeg siv khoom xav tau. Txawm hais tias lub sijhawm xa khoom nyob ntawm qhov ntau thiab tsawg ntawm kev txiav txim thiab qhov nyuaj ntawm nws, peb tseem sim muab cov khoom thiab cov kev daws teeb meem raws sijhawm. Vam tias peb tuaj yeem muaj kev sib raug zoo ua lag luam mus sij hawm ntev.

Kev teeb tsa

| Rooj Ua Haujlwm Loj (hli) | Tshuab Hnyav (kg) | Tag Nrho Lub Hwj Chim (kw) | Ua Haujlwm Voltage (V) | Tus naj npawb ntawm Chav Hydraulic (Pic * Mpa) | Qauv Tswj |

| Txheej kuv: 1500 * 1200Txheej II: 840 * 370 | 1460 xyoo | 11.37 | 380 | 3 * 31.5 | PLC + CNCtus tim tswv khoov |

Cov Kev Ntsuas Tseem Ceeb

| Khoom siv | Kev Txwv Ua Haujlwm (hli) | Lub Zog Tso Tawm Siab Tshaj Plaws (kN) | ||

| Chav xuas nrig ntaus | Tooj liab / Aluminium | ∅32 (tuab ≤ 10) ∅25 (tuab ≤ 15) | 350 | |

| Chav txiav | 15 * 160 (Ib Leeg Shearing) 12 * 160 (Punching Shearing) | 350 | ||

| Chav tsev khoov | 15 * 160 (Ntsug Khoov) 12 * 120 (Kab Rov Qab) | 350 | ||

| * Tag nrho peb chav tuaj yeem xaiv lossis hloov kho raws li kev hloov kho. | ||||