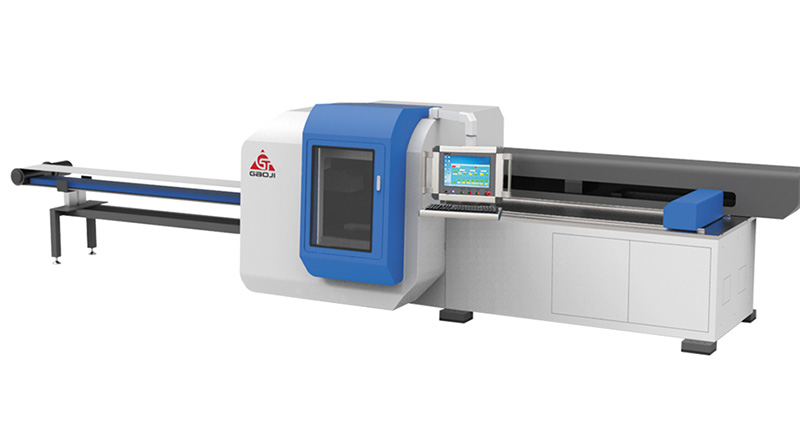

CNC Bus Duct Flaring Tshuab GJCNC-BD

Cov Haujlwm Tseem Ceeb thiab Cov Nta

GJCNC-BD series CNC Busduct Flaring Tshuab yog cov tshuab tsim khoom Hi-Tech tsim los ntawm peb lub tuam txhab, Nrog rau kev pub mis tsis siv neeg, sawing thiab flaring functions (Lwm yam haujlwm ntawm kev xuas nrig ntaus, notching thiab kev sib cuag riveting thiab lwm yam yog xaiv tau). System txais yuav tus kheej tswj system, auto busduct input nrog rau lub sijhawm tiag tiag saib xyuas rau txhua tus txheej txheem, ua kom muaj kev nyab xeeb ntau dua, yooj yim, yoog tau. Txhim kho qib tsis siv neeg thiab lub peev xwm ntawm busduct.

Rogam Software GJBD:Ua ntej ua haujlwm, sau cov ntaub ntawv ntawm busduct thiab txuag, tsis siv neeg tsim PLC code thiab pib txheej txheem.

Cov Txheej Txheem Tsis Siv Neeg:Thauj khoom Bus bar Manually, Aided Clamp pib koom nrog thiab pub, pib clamp, sawing thiab flaring thiab lwm yam (Kev ua haujlwm xaiv tau: xuas nrig ntaus, notching, contactor riveting: Tiv tauj Cabin pub sib cuag tau thiab paub txog kev sib cuag tsis siv neeg riveting.

Ob Chav Clamp:Cov clamps tseem ceeb thiab cov clamps pab. Max X stroke yog 1500 hli. Siv Ob Chav Clamp nrog tus kheej servo motor tswj, paub Auto clamp busbar, kev txuag zog, kev ua haujlwm siab thiab qhov tseeb.

Kev Thauj Khoom Sai:Cov khoom ua tiav lawm raug tso tawm los ntawm kev siv lub tshuab xa khoom sai, Ua haujlwm tau zoo thiab paub tseeb tias tsis muaj khawb rau daim ntawv ua haujlwm.

Tus Qauv HMI:Tib Neeg-Tshuab Sib Txuas Lus (HMI), kev ua haujlwm yooj yim, lub sijhawm saib xyuas cov txheej txheem tiag tiag, Cov ntaub ntawv ceeb toom thiab yooj yim Mould Setup nrog rau cov txheej txheem ua haujlwm.

Kev Sib Kis Ceev Ceev:Cov khoom siv xa khoom siv cov khoom zoo, raug thiab ua haujlwm tau zoo ntawm lub pob ntsia hlau thiab cov lus qhia linear, tsav los ntawm Servo motor, ua kom ntseeg tau tias kev ua haujlwm zoo thiab raug. Txhua yam khoom yog hom nto moo thoob ntiaj teb, zoo thiab lub neej ntev.

Tshuab Qauv:Lub cev tshuab welded nrog high-temperature tempering hauv lub sijhawm, cov qauv yooj yim tab sis zoo rigidness.

Chav Khoom Siv Cuab Yeej (Xaiv Tau):Khaws tag nrho cov cuab yeej thiab hloov pwm yooj yim dua, muaj kev nyab xeeb thiab yooj yim.

| Kev piav qhia | Chav tsev | Cov Qauv | |

| Lub zog | Kev xuas nrig ntaus | kN | 300 |

| Kev txiav qhov | kN | 300 | |

| Kev sib txhuam | kN | 300 | |

| Kev txiav | Qhov Loj Voj Voog | mm | 305 |

| Kev Hloov Pauv | r/m | 2800 | |

| Lub zog tsav tsheb | kw | 3 | |

| Max X1-Txoj Kev Mob Hlwb | mm | 1500 xyoo | |

| Max X2-Txoj Kev Mob Hlwb | mm | 5o0 | |

| Kev Tawm Tsam Siab Tshaj Plaws Y1-Txoj Kev | mm | 350 | |

| Max Y2-Txoj Kev Mob Hlwb | mm | 250 | |

| Qhov Siab Tshaj Plaws | mm | 30 | |

| Chaw Nres Tsheb | Lub voj voog | Teeb tsa | 1 |

| Flare | Teeb tsa | 1 | |

| Ntaus | teeb tsa | 1 (Xaiv) | |

| Qhov Notch | Teeb tsa | 1 (Xaiv) | |

| Tiv tauj Rivet | Teeb tsa | 1 (Xaiv) | |

| Kev Tswj | Axis | 4 | |

| Qhov Kev Ntsuas Qhov Siab | hli/m | ±0.20 | |

| Qhov Chaw Huab Cua | MPa | 0.6 ~ 0.8 | |

| Tag Nrho Lub Hwj Chim | kW | 17 | |

| Qhov Loj Tshaj Plaws ntawm Busbar (LxWxT) | mm | 6000 × 200 × 6 (Lwm Qhov Loj Customized) | |

| Qhov Loj Me Me ntawm Busbar (LxW × T) | mm | 3000 × 30 × 3 (Lwm Qhov Loj Cstomerized) | |

| Tshuab Loj: LxW | mm | 4000 × 2200 | |

| Tshuab Qhov Hnyav | kg | 5000 | |