Hoobkas muag zoo tshaj plaws CNC Bus Arc Machining Center nrog Kub Muag

Peb ib txwm ua haujlwm kom ua ib pab neeg muaj zog kom ntseeg tau tias peb tuaj yeem muab rau koj qhov zoo tshaj plaws thiab tus nqi zoo tshaj plaws rau Lub Hoobkas muag zoo tshaj plaws CNC Bus Arc Machining Center nrog Kub Muag, Zoo siab txais tos koom tes thiab tsim kho nrog peb! peb yuav txuas ntxiv muab cov khoom lag luam nrog cov khoom zoo thiab tus nqi sib tw.

Peb ib txwm ua haujlwm kom ua ib pab neeg uas muaj zog kom ntseeg tau tias peb tuaj yeem muab qhov zoo tshaj plaws rau koj thiab tus nqi zoo tshaj plaws rau koj.Tuam Tshoj CNC Machinery thiab Tshuab Center, Peb lub hom phiaj yog ua kom tau raws li qhov xav tau ntawm peb cov neeg siv khoom thoob ntiaj teb. Peb cov khoom lag luam thiab cov kev pabcuam txuas ntxiv nthuav dav kom tau raws li cov neeg siv khoom xav tau. Peb txais tos cov neeg siv khoom tshiab thiab qub los ntawm txhua qhov chaw ntawm lub neej los tiv tauj peb rau kev sib raug zoo ua lag luam yav tom ntej thiab ua tiav kev vam meej!

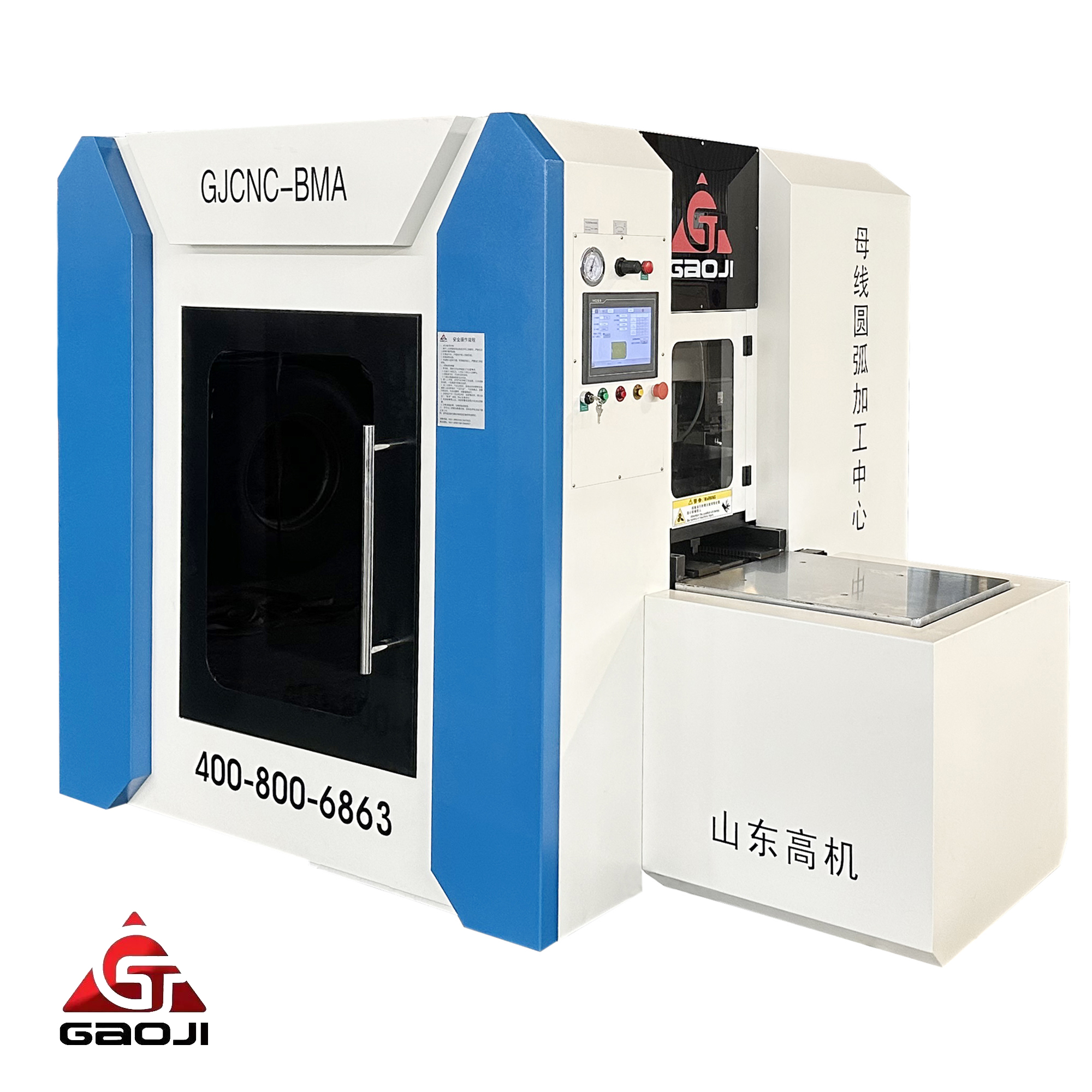

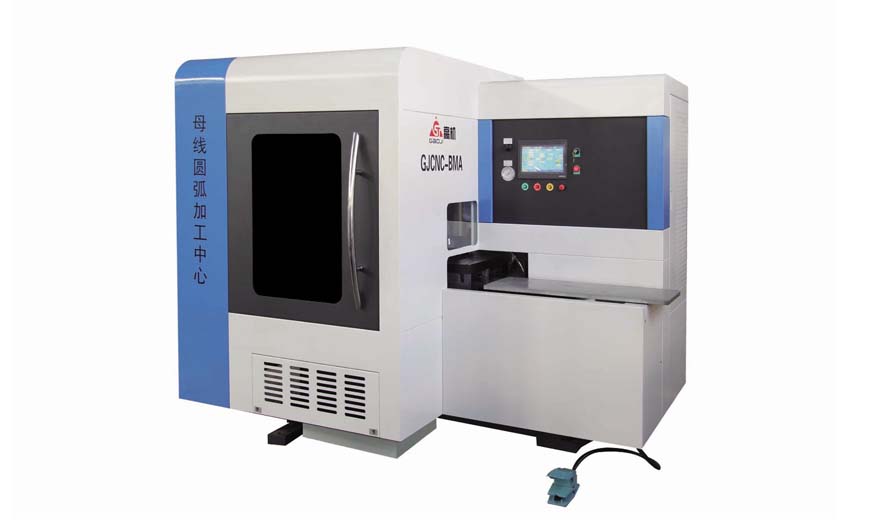

Cov Lus Qhia Txog Khoom

Lub tshuab CNC busbar milling feem ntau ua haujlwm hauv kev milling fillet thiab fillet loj hauv busbar. Nws cia li tsim cov lej program thiab xa cov lej mus rau cov khoom siv raws li qhov yuav tsum tau ua ntawm cov lus qhia busbar thiab cov ntaub ntawv nkag mus rau ntawm qhov screen zaub. Nws yooj yim rau kev khiav lag luam thiab tuaj yeem tshuab busbar arc uas muaj txiaj ntsig zoo nkauj.

Qhov zoo

Lub tshuab no yog siv los ua cov tshuab sectional arc machining rau cov taub hau busbar nrog H≤3-15mm, w≤140mm thiab L≥280mm.

Lub taub hau ntawm lub bar yuav raug tshuab rau cov duab nrog cov qauv ruaj khov.

Cov clamps txais yuav cov thev naus laus zis tsis siv neeg los nias lub taub hau nias zoo dua rau ntawm qhov chaw muaj zog.

Ib lub booster siv rau ntawm lub taub hau nias kom ruaj ntseg ntawm qhov workpiece, ua rau muaj qhov cuam tshuam zoo dua ntawm kev ua haujlwm.

Lub ntiaj teb tus qauv BT40 cuab yeej tuav yog siv rau kev hloov hniav yooj yim, kev ua kom zoo thiab qhov raug siab.

Lub tshuab no siv cov ntsia hlau pob thiab cov lus qhia linear. Cov hlau qhia loj thiab hnyav tau raug xaiv los muab kev ruaj khov zoo dua ntawm tag nrho lub tshuab, txo qhov kev co thiab suab nrov, txhim kho qhov zoo ntawm cov khoom ua haujlwm thiab xyuas kom meej qhov tseeb thiab ua haujlwm tau zoo.

Siv cov khoom ntawm cov khoom lag luam hauv tsev thiab thoob ntiaj teb, lub tshuab no muaj lub neej ua haujlwm ntev thiab tuaj yeem lav qhov zoo.

Cov kev pab cuam siv hauv lub tshuab no yog cov software tsim los ntawm peb lub tuam txhab, uas ua kom paub txog kev ua haujlwm tsis siv neeg hauv kev sau cov lej. Tus neeg teb xov tooj tsis tas yuav nkag siab txog ntau yam lej, thiab nws tsis tas yuav paub siv lub tshuab ua haujlwm ib txwm muaj. Tus neeg teb xov tooj tsuas yog yuav tsum nkag mus rau ntau yam kev teeb tsa los ntawm kev xa mus rau cov duab, thiab cov khoom siv yuav tsim cov lej tshuab cia. Nws siv sijhawm luv dua li kev sau cov lej tes thiab tshem tawm qhov ua yuam kev ntawm cov lej los ntawm kev sau cov lej tes.

Lub tshuab busbar machined hauv lub tshuab no zoo nkauj heev, tsis muaj qhov chaw tso tawm, ua rau lub txee me me kom txuag tau qhov chaw thiab txo qhov kev siv tooj liab.

Peb ib txwm ua haujlwm kom ua ib pab neeg muaj zog kom ntseeg tau tias peb tuaj yeem muab rau koj qhov zoo tshaj plaws thiab tus nqi zoo tshaj plaws rau Lub Hoobkas muag zoo tshaj plaws CNC Bus Arc Machining Center nrog Kub Muag, Zoo siab txais tos koom tes thiab tsim kho nrog peb! peb yuav txuas ntxiv muab cov khoom lag luam nrog cov khoom zoo thiab tus nqi sib tw.

Hoobkas muag zoo tshaj plawsTuam Tshoj CNC Machinery thiab Tshuab Center, Peb lub hom phiaj yog ua kom tau raws li qhov xav tau ntawm peb cov neeg siv khoom thoob ntiaj teb. Peb cov khoom lag luam thiab cov kev pabcuam txuas ntxiv nthuav dav kom tau raws li cov neeg siv khoom xav tau. Peb txais tos cov neeg siv khoom tshiab thiab qub los ntawm txhua qhov chaw ntawm lub neej los tiv tauj peb rau kev sib raug zoo ua lag luam yav tom ntej thiab ua tiav kev vam meej!

Kev teeb tsa

| Qhov Loj (hli) | Qhov hnyav (kg) | Rooj Ua Haujlwm Loj (hli) | Qhov Chaw Huab Cua (Mpa) | Tag Nrho Lub Hwj Chim (kw) |

| 2500 * 2000 | 3300 | 350 * 900 | 0.5~0.9 | 11.5 |

Cov Kev Ntsuas Kev Txawj

| Lub zog tsav (kw) | 7.5 | Lub zog servo (kw) | 2 * 1.3 | Max Torpue (Nm) | 62 |

| Tus Qauv Tuav Cuab Yeej | BT40 | Cov cuab yeej txoj kab uas hla (hli) | 100 | Kev ceev ntawm Spindle (RPM) | 1000 |

| Khoom Siv Dav (hli) | 30~140 | Yam Khoom Siv Ntev Tsawg Kawg Nkaus (hli) | 110 | Khoom Siv Thickness (hli) | 3 ~ 15 |

| X-Axis Stoke (hli) | 250 | Y-Axis Stoke (hli) | 350 | Qhov Ceev Ceev (hli/feeb) | 1500 xyoo |

| Suab ntawm Ballscrew (hli) | 10 | Qhov Tseeb ntawm Txoj Haujlwm (hli) | 0.03 | Kev Pub Noj Ceev (hli/feeb) | 1200 |