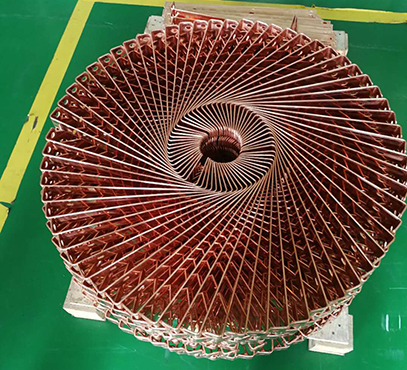

Zoo Zoo Tuam Tshoj CNC Tsis Siv Neeg Tooj Liab Siab Effiency Ua Haujlwm Bending Busbar Tshuab

Lub koom haum ua raws li lub tswv yim ua haujlwm "kev tswj hwm kev tshawb fawb, kev ua tau zoo tshaj plaws thiab kev ua tau zoo tshaj plaws, cov neeg siv khoom zoo tshaj plaws rau Zoo Zoo Tuam Tshoj CNC Tsis Siv Neeg Tooj Liab Siab Effiency Ua Haujlwm Bending Busbar Tshuab, Peb cog lus tias yuav sim peb qhov zoo tshaj plaws los xa koj cov khoom lag luam zoo thiab pheej yig thiab cov kev pabcuam.

Lub koom haum ua raws li lub tswv yim ua haujlwm "kev tswj hwm kev tshawb fawb, kev ua tau zoo tshaj plaws thiab kev ua tau zoo tshaj plaws, cov neeg siv khoom zoo tshaj plaws rauTuam Tshoj Tsis Siv Neeg Busbar Tshuab, Tshuab Tooj Liab Busbar, Peb tau paub txog peb cov neeg siv khoom xav tau tag nrho. Peb muab cov khoom lag luam zoo, cov nqi sib tw thiab cov kev pabcuam zoo tshaj plaws. Peb xav tsim kom muaj kev sib raug zoo ua lag luam zoo thiab kev phooj ywg nrog koj yav tom ntej.

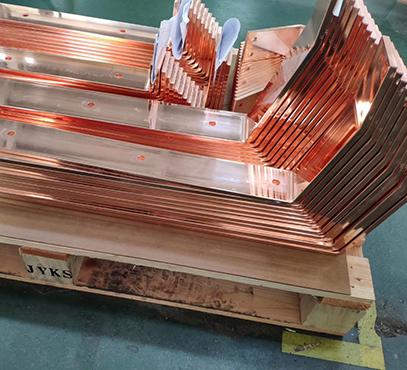

Cov Lus Qhia Txog Khoom

GJCNC-BB Series yog tsim los khoov cov khoom siv busbar kom zoo thiab raug

CNC Busbar Bender yog cov khoom siv tshwj xeeb busbar bending ua los ntawm lub computer, Los ntawm X-axis thiab Y-axis kev sib koom tes, kev pub mis tes, lub tshuab tuaj yeem ua tiav ntau hom kev khoov xws li kev khoov theem, kev khoov ntsug los ntawm kev xaiv cov pwm sib txawv. Lub tshuab tuaj yeem phim nrog GJ3D software, uas tuaj yeem xam qhov ntev ntawm kev khoov. Lub software tuaj yeem nrhiav qhov sib lawv liag ntawm kev khoov rau cov khoom ua haujlwm uas xav tau ntau zaus khoov thiab kev tswj hwm kev tswj hwm tau ua tiav.

Tus Neeg Ua Yeeb Yam Tseem Ceeb

Cov yam ntxwv ntawm GJCNC-BB-30-2.0

Lub tshuab no siv cov qauv khoov kaw tshwj xeeb, nws muaj cov khoom zoo tshaj plaws ntawm kev khoov kaw, thiab nws kuj muaj qhov yooj yim ntawm kev khoov qhib.

Lub Chav Khoov (Y-axis) muaj lub luag haujlwm ntawm kev them nyiaj yuam kev ntawm lub kaum sab xis, nws qhov tseeb khoov tuaj yeem ua tau raws li qhov kev ua tau zoo siab. ± 01 °.

Thaum nws nyob rau hauv ntsug bending, lub tshuab muaj lub luag haujlwm ntawm nws tus kheej clamping thiab tso tawm, qhov ua tau zoo ntawm kev ua haujlwm tau zoo dua piv rau phau ntawv clamping thiab tso tawm.

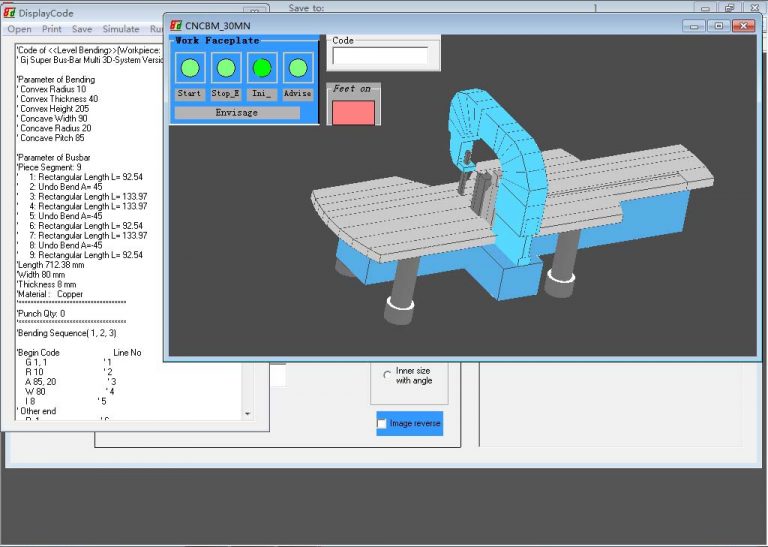

GJ3D Programming software

Yuav kom paub txog kev sau code tsis siv neeg, yooj yim thiab yooj yim ua haujlwm, peb tsim thiab tsim cov software tsim tshwj xeeb GJ3D. Cov software no tuaj yeem suav txhua hnub hauv tag nrho cov txheej txheem busbar, yog li nws tuaj yeem zam kev pov tseg cov khoom siv los ntawm qhov yuam kev ntawm kev sau code; thiab ua thawj lub tuam txhab siv 3D thev naus laus zis rau kev lag luam ua busbar, cov software tuaj yeem ua pov thawj tag nrho cov txheej txheem nrog 3D qauv uas meej dua thiab pab tau dua li yav dhau los.

Yog tias koj xav tau hloov kho cov ntaub ntawv teeb tsa ntawm cov khoom siv lossis cov txheej txheem tuag yooj yim, koj tuaj yeem sau hnub tim nrog lub tshuab no.

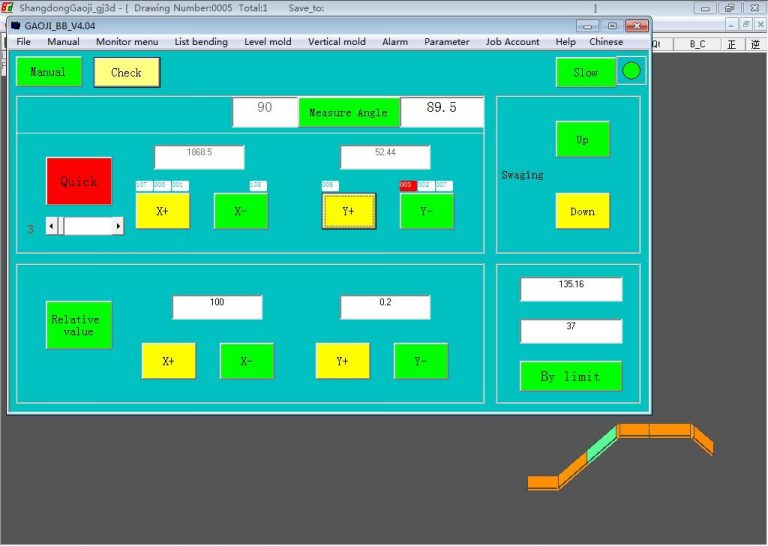

Kov Screen

Tib neeg-lub computer interface, kev ua haujlwm yooj yim thiab tuaj yeem ua pov thawj lub sijhawm ua haujlwm ntawm qhov kev pab cuam, lub vijtsam tuaj yeem qhia cov ntaub ntawv ceeb toom ntawm lub tshuab; nws tuaj yeem teeb tsa cov txheej txheem tuag yooj yim thiab tswj kev ua haujlwm ntawm lub tshuab.

Kev Ua Haujlwm Ceev Ceev

Kev sib kis tau zoo ntawm lub pob ntsia hlau, sib koom ua ke nrog kev qhia ncaj nraim, kev ua haujlwm raug siab, ua haujlwm sai, siv tau ntev thiab tsis muaj suab nrov.

Khoom ua haujlwm

Lub koom haum ua raws li lub tswv yim ua haujlwm "kev tswj hwm kev tshawb fawb, kev ua tau zoo tshaj plaws thiab kev ua tau zoo tshaj plaws, cov neeg siv khoom zoo tshaj plaws rau Zoo Zoo Tuam Tshoj CNC Tsis Siv Neeg Tooj Liab Siab Effiency Ua Dabtsi Yog Khoov Xuas Tes Txiav Tshuab Busbar Arc Machining Chamfering Tshuab, Peb cog lus tias yuav sim peb qhov zoo tshaj plaws los xa koj cov khoom lag luam zoo thiab pheej yig.

Zoo ZooTuam Tshoj Tsis Siv Neeg Busbar Tshuab, Tshuab Tooj Liab Busbar, Peb tau paub txog peb cov neeg siv khoom xav tau tag nrho. Peb muab cov khoom lag luam zoo, cov nqi sib tw thiab cov kev pabcuam zoo tshaj plaws. Peb xav tsim kom muaj kev sib raug zoo ua lag luam zoo thiab kev phooj ywg nrog koj yav tom ntej.

Cov Kev Ntsuas Kev Txawj

| Tag Nrho Qhov Hnyav (kg) | 2300 | Qhov Loj (hli) | 6000 * 3500 * 1600 |

| Siab Tshaj Plaws Dej (Mpa) | 31.5 | Lub Hwj Chim Tseem Ceeb (kw) | 6 |

| Lub Zog Tso Tawm (kn) | 350 | Max Stoke ntawm lub tog raj kheej khoov (hli) | 250 |

| Qhov Loj Tshaj Plaws ntawm Cov Khoom Siv (Ntsug Khoov) | 200 * 12 hli | Qhov Loj Tshaj Plaws ntawm Cov Khoom Siv (Khoov Kab Rov Tav) | 120 * 12 hli |

| Qhov ceev tshaj plaws ntawm lub taub hau khoov (m / min) | 5 (Hom Ceev)/1.25 (Hom Qis) | Lub kaum sab xis siab tshaj plaws (degree) | 90 |

| Qhov ceev tshaj plaws ntawm cov khoom siv thaiv sab nraud (m / min) | 15 | Stoke ntawm cov khoom siv sab nraud thaiv (X Axis) | 2000 xyoo |

| Kev Khoov Qhov Tseeb (degree) | Kev them nyiaj pib <± 0.5Kev them nyiaj ntawm tes <± 0.2 | Qhov dav ntawm qhov khoov ntawm U-puab tsawg kawg nkaus (hli) | 40 (Ceeb Toom: thov nrog peb lub tuam txhab tham thaum koj xav tau hom me dua) |