Tus nqi qis tshaj plaws rau Tuam Tshoj CNC Busbar Punching thiab Shearing Tshuab

Peb muaj peb cov neeg ua haujlwm muag khoom, cov neeg ua haujlwm tsim qauv, pab pawg kws tshaj lij, cov neeg ua haujlwm QC thiab cov neeg ua haujlwm pob khoom. Tam sim no peb muaj cov txheej txheem tswj hwm zoo rau txhua txoj hauv kev. Tsis tas li ntawd, peb cov neeg ua haujlwm txhua tus muaj kev paub dhau los hauv kev luam ntawv rau Tus Nqi Qis Tshaj Plaws rau Tuam Tshoj CNC Busbar Punching thiab Shearing Tshuab, Peb tab tom nrhiav kev koom tes zoo dua nrog cov neeg siv khoom txawv teb chaws nyob ntawm kev sib koom tes ntxiv. Rau txhua tus neeg uas xav paub txog peb cov khoom thiab cov kev daws teeb meem, nco ntsoov tiv tauj peb kom paub ntau ntxiv.

Peb muaj peb cov neeg ua haujlwm muag khoom, cov neeg ua haujlwm style, pab pawg kws tshaj lij, cov neeg ua haujlwm QC thiab cov neeg ua haujlwm pob khoom. Tam sim no peb muaj cov txheej txheem tswj hwm zoo rau txhua txoj hauv kev. Tsis tas li ntawd, peb cov neeg ua haujlwm txhua tus muaj kev paub txog kev luam ntawv rauTuam Tshoj CNC Busbar Punching Tshuab, Tshuab Xuas Qhov, Peb tau xa peb cov khoom mus thoob plaws ntiaj teb, tshwj xeeb tshaj yog Tebchaws Meskas thiab Tebchaws Europe. Ntxiv mus, tag nrho peb cov khoom raug tsim nrog cov khoom siv siab heev thiab cov txheej txheem QC nruj kom ntseeg tau tias zoo. Yog tias koj xav tau ib qho ntawm peb cov khoom, thov tsis txhob yig tiv tauj peb. Peb yuav sim peb qhov zoo tshaj plaws kom tau raws li koj xav tau.

Cov Lus Qhia Txog Khoom

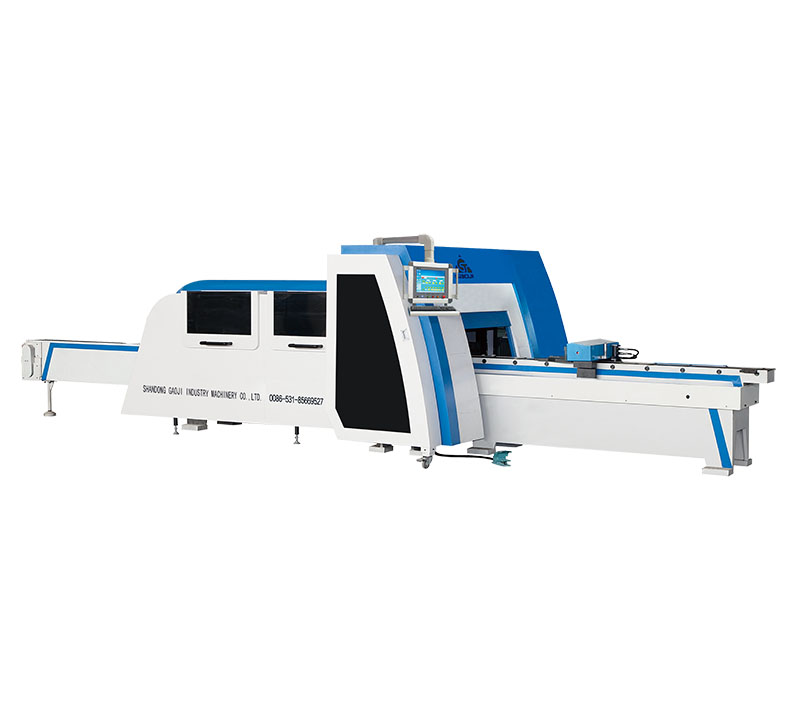

GJCNC-BP-50 yog cov khoom siv tshaj lij uas tsim los ua cov busbar kom zoo thiab raug.

Thaum lub sijhawm ua cov khoom siv no tuaj yeem hloov cov clamps, uas yog qhov zoo heev tshwj xeeb tshaj yog rau cov busbar ntev. Nrog cov txheej txheem ua cov tuag hauv cov cuab yeej qiv, cov khoom siv no tuaj yeem ua cov busbar los ntawm kev xuas nrig (qhov puag ncig, qhov oblong thiab lwm yam), embossing, shearing, grooving, txiav filleted ces kaum thiab lwm yam. Cov khoom ua tiav yuav raug xa los ntawm lub conveyor.

Cov khoom siv no tuaj yeem phim nrog CNC bender thiab tsim cov kab ua haujlwm busbar.

Tus Neeg Ua Yeeb Yam Tseem Ceeb

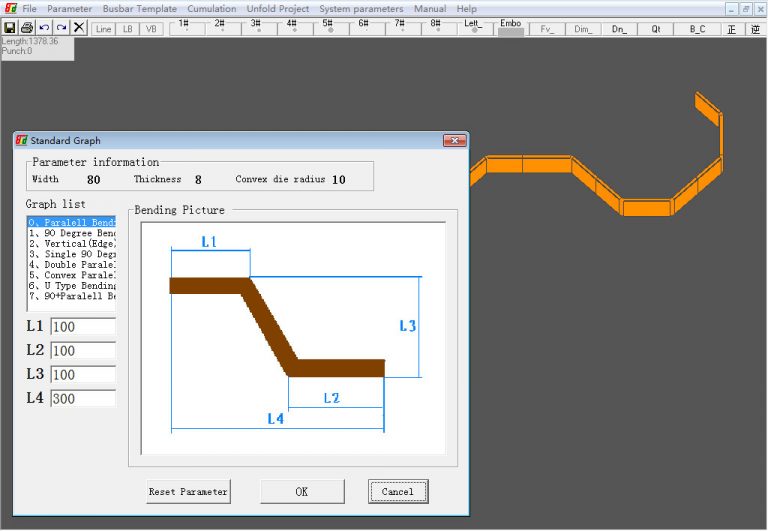

GJ3D / software sau ntawv

GJ3D yog ib qho software tsim tshwj xeeb uas pab tsim cov busbar ua haujlwm. Uas tuaj yeem pib program cov lej tshuab, xam txhua hnub ua haujlwm, thiab qhia koj qhov kev sim ntawm tag nrho cov txheej txheem uas yuav nthuav qhia qhov kev hloov pauv ntawm busbar ib kauj ruam zuj zus kom meej. Cov cim no ua rau nws yooj yim thiab muaj zog kom tsis txhob muaj kev sau code nyuaj nrog cov lus tshuab. Thiab nws muaj peev xwm ua pov thawj tag nrho cov txheej txheem thiab tiv thaiv cov khoom pov tseg los ntawm kev nkag tsis raug.

Tau ntau xyoo lub tuam txhab tau ua tus thawj coj hauv kev siv cov txheej txheem 3D duab rau kev lag luam ua busbar. Tam sim no peb tuaj yeem nthuav qhia rau koj qhov zoo tshaj plaws cnc tswj thiab tsim software hauv Es Xias.

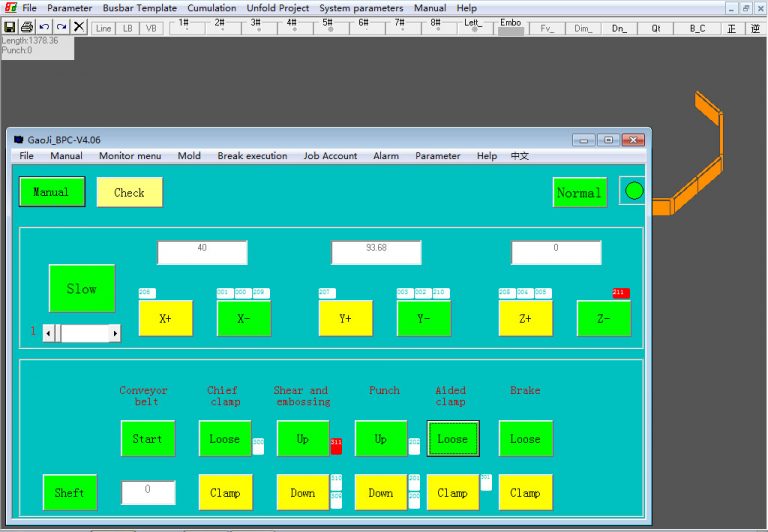

Kev sib txuas lus ntawm tib neeg thiab lub khoos phis tawj

Yuav kom nthuav qhia kev ua haujlwm zoo dua thiab cov ntaub ntawv muaj txiaj ntsig zoo dua. Cov khoom siv muaj 15 "RMTP ua tib neeg-lub computer interface. Nrog rau chav tsev no koj tuaj yeem muaj cov ntaub ntawv meej ntawm tag nrho cov txheej txheem tsim khoom lossis txhua lub tswb ceeb toom yuav tshwm sim thiab tswj cov khoom siv los ntawm ib txhais tes.

Yog tias koj xav tau hloov kho cov ntaub ntawv teeb tsa ntawm cov khoom siv lossis cov txheej txheem tuag yooj yim, koj tuaj yeem sau hnub tim nrog lub tshuab no.

Cov Qauv Tshuab

Yuav kom tsim tau ib lub tshuab uas ruaj khov, siv tau zoo, raug, thiab siv tau ntev, peb xaiv cov ntsia hlau uas muaj qhov tseeb, cov lus qhia ncaj qha los ntawm Taiwan HIWIN thiab lub tshuab servo los ntawm YASKAWA ntxiv rau peb lub tshuab ob lub clamp tshwj xeeb. Tag nrho cov no saum toj no tsim tau ib lub tshuab kis tau zoo raws li koj xav tau.

Peb tsim cov kev pab cuam hloov pauv tsis siv neeg kom ua rau lub kaw lus clamp ua haujlwm tau zoo dua tshwj xeeb tshaj yog rau kev ua haujlwm ntev ntawm lub busbar, thiab tseem tuaj yeem txo qhov kev ua haujlwm ntawm tus neeg teb xov tooj. Tsim kom muaj txiaj ntsig ntau dua rau peb cov neeg siv khoom.

Muaj ob hom:

GJCNC-BP-50-8-2.0/SC (Rau qhov xuas nrig, ib qho txiab, ib qho nias)

GJCNC-BP-50-8-2.0/C (Yim lub xuas nrig ntaus, ib rab txiab)

Koj tuaj yeem xaiv cov qauv koj xav tau

Kev Ntim Khoom Tawm Mus

Peb muaj peb cov neeg ua haujlwm muag khoom, cov neeg ua haujlwm tsim qauv, pab pawg kws tshaj lij, cov neeg ua haujlwm QC thiab cov neeg ua haujlwm pob khoom. Tam sim no peb muaj cov txheej txheem tswj hwm zoo rau txhua txoj hauv kev. Tsis tas li ntawd, peb cov neeg ua haujlwm txhua tus muaj kev paub dhau los hauv kev luam ntawv rau Tus Nqi Qis Tshaj Plaws rau Tuam Tshoj CNC Busbar Punching thiab Shearing Tshuab, Peb tab tom nrhiav kev koom tes zoo dua nrog cov neeg siv khoom txawv teb chaws nyob ntawm kev sib koom tes ntxiv. Rau txhua tus neeg uas xav paub txog peb cov khoom thiab cov kev daws teeb meem, nco ntsoov tiv tauj peb kom paub ntau ntxiv.

Tus nqi qis tshaj plaws rauTuam Tshoj CNC Busbar Punching Tshuab, Tshuab Xuas Qhov, Peb tau xa peb cov khoom mus thoob plaws ntiaj teb, tshwj xeeb tshaj yog Tebchaws Meskas thiab Tebchaws Europe. Ntxiv mus, tag nrho peb cov khoom raug tsim nrog cov khoom siv siab heev thiab cov txheej txheem QC nruj kom ntseeg tau tias zoo. Yog tias koj xav tau ib qho ntawm peb cov khoom, thov tsis txhob yig tiv tauj peb. Peb yuav sim peb qhov zoo tshaj plaws kom tau raws li koj xav tau.

Cov Kev Ntsuas Tseem Ceeb

| Qhov Loj (hli) | 7500 * 2980 * 1900 | Qhov hnyav (kg) | 7600 | Daim Ntawv Pov Thawj | CE ISO | ||

| Lub Hwj Chim Tseem Ceeb (kw) | 15.3 | Lub zog hluav taws xob nkag | 380/220V | Qhov Chaw Fais Fab | Hydraulic | ||

| Lub Zog Tso Tawm (kn) | 500 | Kev Ceev Xuas Nrig (hpm) | 120 | Kev Tswj Axis | 3 | ||

| Qhov Loj Tshaj Plaws Khoom Siv (hli) | 6000 * 200 * 15 | Max Punching Dies | 32 hli (Tuab ntawm cov khoom siv hauv qab 12 hli) | ||||

| Qhov Chaw Ceev(X-axis) | 48m/feeb | Stroke ntawm Punching Lub Tog Raj Kheej | 45 hli | Kev Rov Ua Dua Qhov Chaw | ±0.20 hli/m | ||

| Mob stroke siab tshaj plaws(hli) | X-axisY-axisZ-axis | 2000 xyoo530350 | Tus nqiofTuag | Kev xuas nrig ntausTxiavKev luam tawm | 6/81/11/0 | ||

Kev teeb tsa

| Cov Khoom Tswj | Cov Khoom Siv Kis | ||

| PLC | OMRON | Kev Qhia Tawm Tseeb | Taiwan HIWIN |

| Cov Sensors | Schneider hluav taws xob | Precision lub pob ntsia hlau (4th series) | Taiwan HIWIN |

| Khawm Tswj | OMRON | Kev txhawb nqa pob ntsia hlau | Nyiv NSK |

| Kov Screen | OMRON | Cov Khoom Siv Hydraulic | |

| Khoos phis tawj | Lenovo | Lub Tshuab Hluav Taws Xob Hluav Taws Xob Siab | Ltalis |

| AC Contactor | ABB | Cov yeeb nkab siab | Ltalis MANULI |

| Lub Tshuab Hluav Taws Xob | ABB | Twj tso kua siab | Ltalis |

| Lub Cev Muaj Zog Servo | YASKAWA | Cov software tswj thiab 3D kev txhawb nqa software | GJ3D (3D kev txhawb nqa software tsim los ntawm peb lub tuam txhab) |

| Tus Tsav Tsheb Servo | YASKAWA | ||