Tus nqi hais rau Tuam Tshoj Multi Function Hydraulic Busbar Processing Machine

Peb cog lus tias yuav muab rau koj tus nqi siab, cov khoom zoo heev thiab cov kev daws teeb meem zoo tshaj plaws, nrog rau kev xa khoom sai rau tus nqi hais rau Tuam Tshoj Multi Function Hydraulic Busbar Processing Machine, Peb cov neeg ua haujlwm paub txog kev ua haujlwm yuav txaus siab rau koj qhov kev txhawb nqa. Peb zoo siab tos txais koj kom nres los ntawm peb lub vev xaib thiab lub tuam txhab thiab xa koj cov lus nug rau peb.

Peb cog lus tias yuav muab cov nqi pheej yig, cov khoom zoo heev thiab cov kev daws teeb meem zoo tshaj plaws rau koj, thiab xa khoom sai rauTshuab Busbar, Tuam Tshoj CNC TshuabPeb cov kev daws teeb meem muaj cov kev cai lees paub hauv tebchaws rau cov khoom tsim nyog, zoo, pheej yig, tau txais tos los ntawm cov neeg thoob plaws ntiaj teb. Peb cov khoom yuav txuas ntxiv txhim kho hauv kev txiav txim thiab tos ntsoov yuav koom tes nrog koj, Qhov tseeb, ib qho ntawm cov khoom ntawd yuav tsum yog qhov koj xav tau, nco ntsoov qhia rau peb paub. Peb yuav txaus siab muab rau koj tus nqi thaum tau txais cov kev xav tau tag nrho.

Kev piav qhia txog khoom

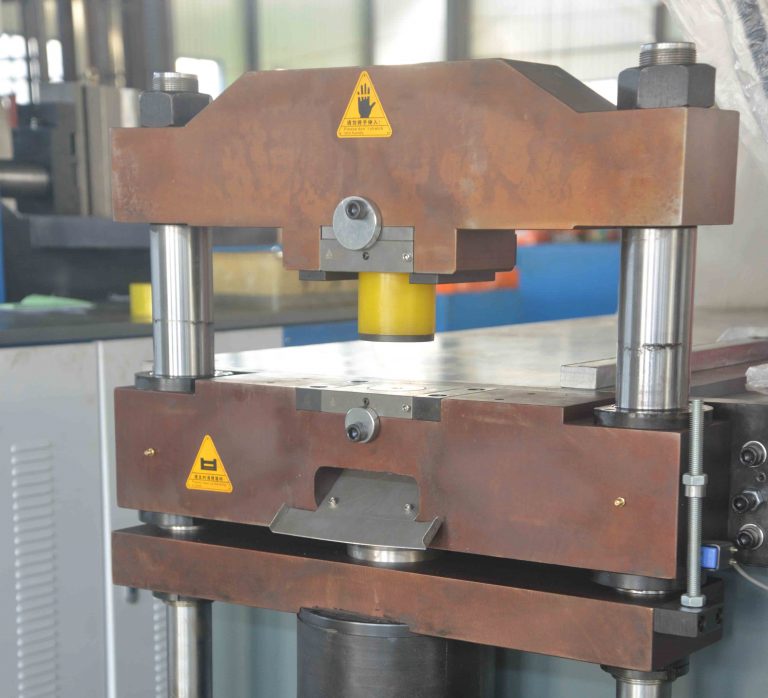

BM603-S-3 Series yog lub tshuab ua haujlwm ntau lub busbar uas tsim los ntawm peb lub tuam txhab. Cov khoom siv no tuaj yeem ua punching, shearing thiab bending tib lub sijhawm, thiab tsim tshwj xeeb rau kev ua cov busbar loj.

Qhov zoo

Lub tshuab xuas nrig siv lub ncej ncej, muaj zog txaus, thiab siv tau ntev yam tsis muaj kev hloov pauv. Lub tshuab xuas nrig siv lub tshuab tswj tus lej los ua kom muaj kev raug siab thiab siv tau ntev, thiab ntau yam txheej txheem xws li lub qhov puag ncig, lub qhov puag ncig ntev, lub qhov plaub fab, lub qhov ob npaug lossis embossing tuaj yeem ua tiav los ntawm kev hloov lub pwm.

Lub tshuab txiav kuj tseem siv cov ncej kem uas yuav muab lub zog ntau dua rau riam, riam sab saud thiab sab qis tau teeb tsa ntsug parallelly, ib qho shearing hom ua kom lub kerf du thiab tsis muaj pov tseg.

Lub tshuab khoov tuaj yeem ua cov txheej txheem khoov theem, khoov ntsug, khoov lub luj tshib, txuas lub davhlau ya nyob twg, Z-puab lossis khoov ntswj los ntawm kev hloov cov tuag.

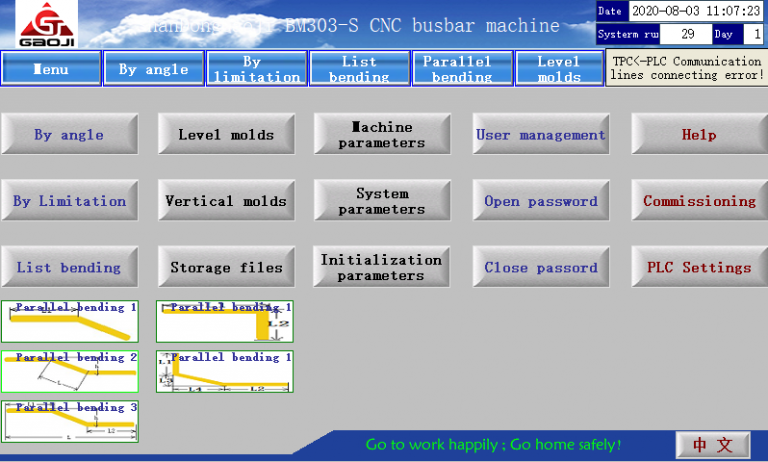

Chav tsev no yog tsim los kom tswj tau los ntawm PLC qhov chaw, cov khoom no koom tes nrog peb qhov kev tswj hwm tuaj yeem ua kom koj muaj kev paub ua haujlwm yooj yim thiab ua haujlwm raug siab, thiab tag nrho cov khoom khoov tso rau ntawm lub platform ywj pheej uas ua kom tag nrho peb chav tuaj yeem ua haujlwm tib lub sijhawm.

Vaj huam sib luag tswj, tib neeg-tshuab interface: nws software yooj yim rau kev khiav lag luam, muaj lub luag haujlwm khaws cia, thiab yooj yim rau kev ua haujlwm rov ua dua. Kev tswj hwm machining siv txoj kev tswj tus lej, thiab qhov tseeb machining yog siab.

Peb cog lus tias yuav muab rau koj tus nqi siab, cov khoom zoo heev thiab cov kev daws teeb meem zoo tshaj plaws, nrog rau kev xa khoom sai rau tus nqi hais rau Tuam Tshoj Multi Function Hydraulic Busbar Processing Machine, Peb cov neeg ua haujlwm paub txog kev ua haujlwm yuav txaus siab rau koj qhov kev txhawb nqa. Peb zoo siab tos txais koj kom nres los ntawm peb lub vev xaib thiab lub tuam txhab thiab xa koj cov lus nug rau peb.

Tus nqi hais rauTuam Tshoj CNC TshuabPeb cov kev daws teeb meem muaj cov kev cai lees paub hauv tebchaws rau cov khoom tsim nyog, zoo, pheej yig, tau txais tos los ntawm cov neeg thoob plaws ntiaj teb. Peb cov khoom yuav txuas ntxiv txhim kho hauv kev txiav txim thiab tos ntsoov yuav koom tes nrog koj, Qhov tseeb, ib qho ntawm cov khoom ntawd yuav tsum yog qhov koj xav tau, nco ntsoov qhia rau peb paub. Peb yuav txaus siab muab rau koj tus nqi thaum tau txais cov kev xav tau tag nrho.

Cov Kev Ntsuas Kev Txawj

| Tag Nrho Qhov Hnyav (kg) | 2300 | Qhov Loj (hli) | 6000 * 3500 * 1600 |

| Siab Tshaj Plaws Dej (Mpa) | 31.5 | Lub Hwj Chim Tseem Ceeb (kw) | 6 |

| Lub Zog Tso Tawm (kn) | 350 | Max Stoke ntawm lub tog raj kheej khoov (hli) | 250 |

| Qhov Loj Tshaj Plaws ntawm Cov Khoom Siv (Ntsug Khoov) | 200 * 12 hli | Qhov Loj Tshaj Plaws ntawm Cov Khoom Siv (Khoov Kab Rov Tav) | 120 * 12 hli |

| Qhov ceev tshaj plaws ntawm lub taub hau khoov (m / min) | 5 (Hom Ceev)/1.25 (Hom Qis) | Lub kaum sab xis siab tshaj plaws (degree) | 90 |

| Qhov ceev tshaj plaws ntawm cov khoom siv thaiv sab nraud (m / min) | 15 | Stoke ntawm cov khoom siv sab nraud thaiv (X Axis) | 2000 xyoo |

| Kev Khoov Qhov Tseeb (degree) | Kev them nyiaj pib <± 0.5Kev them nyiaj ntawm tes <± 0.2 | Qhov dav ntawm qhov khoov ntawm U-puab tsawg kawg nkaus (hli) | 40 (Ceeb Toom: thov nrog peb lub tuam txhab tham thaum koj xav tau hom me dua) |